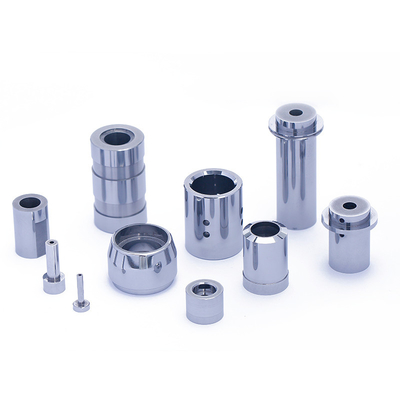

Kinyet 고정밀 펀치 금형 부품 텅스텐 카바이드 스탬핑 다이

자동차 산업용 고정밀 텅스텐 카바이드 펀치 다이

텅스텐 카바이드(탄화텅스텐)는 높은 정확도, 내마모성 및 충격 강도로 인해 자동차 펀치 다이에 이상적인 소재입니다. 이러한 부품은 다양한 자동차 제조 공정에 필수적입니다.

적용 분야

- 자동차 부품용 단조 금형 (열간 단조, 냉간 단조, 정밀 단조)

- 자동차용 체결 제품

- 자동차 스프링 제조용 정밀 공구

- 자동차 시스템용 다양한 정밀 기어 부품

제품 사양

- 표면 조도: RZ~~0.2um / F1.0mm/min

- 정확도: ±0.001mm

- 맞춤 제작: 완벽한 맞춤형 솔루션 제공 (비표준 주문만)

적합한 재료

| 재료 |

특성 |

| 텅스텐 카바이드 |

높은 내마모성과 열적 안정성을 가진 매우 단단한 재료입니다. 재료 비용이 더 높음에도 불구하고 다이 강철보다 훨씬 긴 수명을 제공합니다. |

| 세라믹 |

우수한 고온 저항성 (180°C ~ 1200°C) 및 내화학성. 알루미나, 지르코니아, 탄화규소 및 질화규소 세라믹을 포함합니다. |

| HSS (고속 강) |

우수한 내마모성과 인성, 소량 생산 또는 재료 인성이 필요한 응용 분야에 이상적입니다. |

가공 기술

- 원통 연삭

- 내부 원형 연삭

- 광학 프로파일 연삭

- 평면 연삭

- 나사 가공

- 중/저속 와이어 커팅

- 미러 방전 가공

당사의 장점

- 첨단 기술: 고정밀도로 복잡한 형상 형성 가능

- 효율적인 가공: 빠른 납기로 짧은 생산 주기

- 제품 품질: ±0.003mm까지의 정확도로 일관된 품질

- 기밀 유지: NDA 옵션을 포함한 삼중 보호 조치

- 생산 능력: 첨단 장비를 갖춘 여러 생산 라인

- 비용 효율성: 최적화된 설계 및 재료 선택을 통한 경쟁력 있는 가격

Kinyet은 텅스텐 재료 R&D를 전문으로 하며, 경쟁력 있는 가격으로 고정밀, 장수명 금형 솔루션을 제공하기 위해 새로운 기술과 고급 장비에 지속적으로 투자합니다. 이제 Drow와 합병하여 더욱 뛰어난 제품을 만들 수 있게 되었습니다.

품질 기준

- 내마모성

- 정밀도

- 내식성

- 충격 강도

- 인성

- 탄성 계수/강성

- 횡 파괴 강도

자주 묻는 질문

Q1: 특수 펀치 금형 또는 펀치 다이 부품을 생산하십니까?

예, 다양한 까다로운 응용 분야 및 재료에 대한 복잡한 펀치 다이 개념을 현실로 구현하는 맞춤형 금형 제작을 전문으로 합니다.

Q2: 샘플 주문에 소량을 받으십니까? 맞춤 제작의 MOQ는 무엇입니까?

예, 1개의 MOQ로 샘플 주문을 받습니다. 샘플 리드 타임은 일반적으로 10-15일이며, 특별 요구 사항에 따라 협의 가능합니다.

Q3: 배송 방법은 무엇입니까?

고객 요구 사항에 따라 가장 적합한 운송 서비스를 제공합니다.

Q4: 지불 조건은 무엇입니까?

T/T를 통한 30% 보증금, 배송 전 70% 잔액 지불. 최종 결제 전에 제품 사진을 제공합니다.

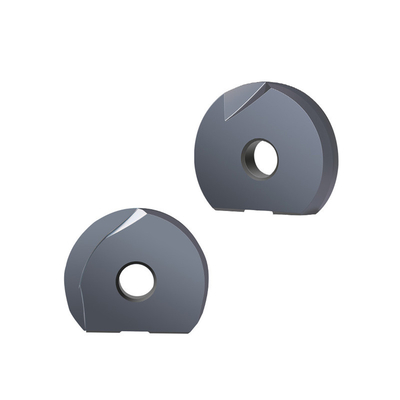

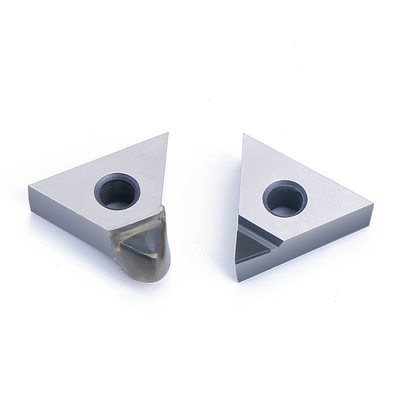

Q5: 어떤 제품을 공급할 수 있습니까?

카바이드 인서트, 엔드밀, 드릴, 보링 공구, 절삭 공구 및 맞춤형 정밀 금형.

Q6: OEM 및 ODM 서비스를 제공하십니까?

예, 10년 이상의 OEM 경험을 보유하고 있습니다. 당사의 R&D 팀은 다양한 고객 요구에 맞는 전문적인 설계 솔루션을 제공합니다.

Q7: 배송 전에 모든 상품을 테스트합니까?

예, ISO9001 표준에 따라 100% 테스트를 수행하며 생산 전반에 걸쳐 엄격한 품질 관리를 수행합니다.

Q8: 중국에 있는 저희 포워더에게 제품을 보낼 수 있습니까?

예, 중국에 있는 지정된 포워더에게 배송을 주선할 수 있습니다.

귀하의 메시지는 20-3,000 자 사이 여야합니다!

귀하의 메시지는 20-3,000 자 사이 여야합니다! 이메일을 확인하십시오!

이메일을 확인하십시오!  귀하의 메시지는 20-3,000 자 사이 여야합니다!

귀하의 메시지는 20-3,000 자 사이 여야합니다! 이메일을 확인하십시오!

이메일을 확인하십시오!